Basic Info.

Model NO.

GSGZA-CNC-7000

Certification

CE, ISO 9001

Condition

New

Product Name

CNC Axis Aluminium Milling Machine Center

Function

Milling Drilling Aluminium Profiles

Workable Aluminium Material Length

7000mm

Spindle Rotating Angle

-90 Degree~0~90 Degree

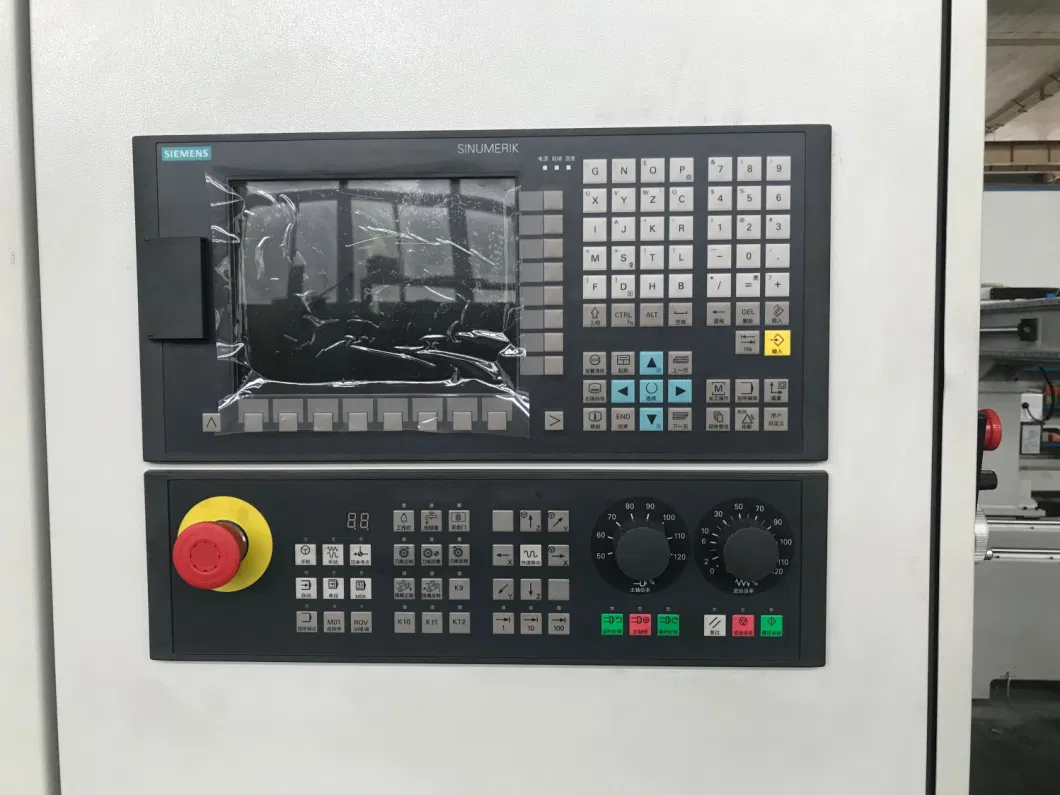

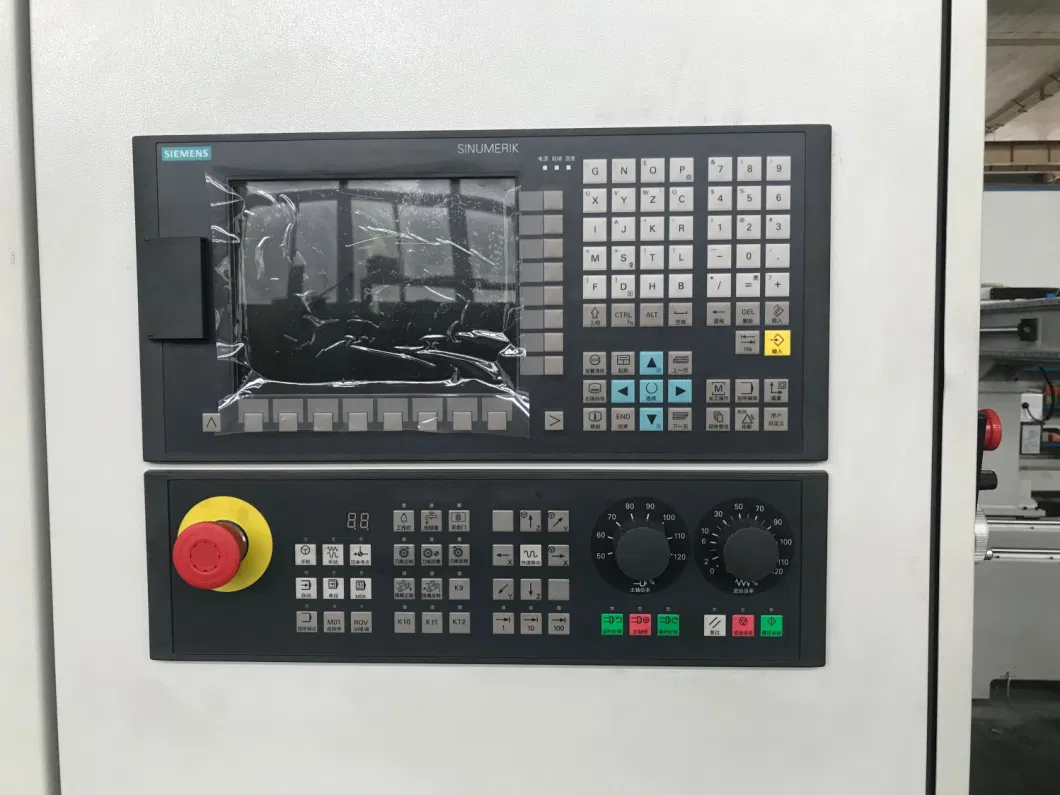

Control System

Siemens

Machine Type

Fully Automatic

Material Type

Aluminium Profile

Usage

Facade Curtain Wall Fbarication

Spindle Type

High Speed Electrical Motorized

Spindle Brand

Hsd From Italy

Transport Package

Standard Export Package or as Requirements

Specification

About4500kg

Trademark

Tianchen

Origin

China

HS Code

84614090

Production Capacity

200 Sets/Year

Product Description

High Speed 4 Axis Aluminium CNC Machining Center

GSGZA-CNC-7000

GSGZA-CNC-7000

Machine Features:

1. This machine is designed for taping, milling, processing launders, and mounting holes, lock holes and other special slots for diversified curtain wall profile and aluminum door and window profile.

2. It adopts the original Italy imported high-speed electric spindle, and it can work at any angle within ± 900, with high efficiency.

3. It adopts high-quality exclusive industrial computer control system with good user operating interface, graphic programming and machining tracing interface. This processing interface can show the related dates directly.

4. It adopts original imported control system and servo-motor and high quality ball screw, linear guide rail pair and bearing to insure the high precision.

5. The cutter storage has12 cutter positions, cutter change automatically.

6. The fixture position can be adjusted freely.

7. The double working benches allow to process two workpieces or two kinds of profiles at the same time.

8. With half-close safeguard device to insure the personal safety of the operator.

7. The position of clamping device can put freely.

Technical Specifications:

| X-way range | 7000mm |

| Y-way range | 1300mm |

| Z-way range | 550mm |

| X-way speed | 0~60m/min |

| Y-way speed | 0~30m/min |

| Z-way speed | 0~20m/min |

| Main shaft rev./power | 0~18000rpm/7.5kw |

| Gyrating range | -90~0~+90 |

| Cutter magazine | 12 cutter positions, cutter auto-change is available in the program |

| Cutter max length | 165mm |

| Pneumatic pressure | 0.5-0.8MPa |

| Power supply | 380V/50Hz |

| Total power | 13kw |

| Quantity of clamps | 8 sets |

| Lubricating & cooling | auto lubricating spray cooling |

| Work area(W×H×L) | 650×250×7000mm |

| Contour Dimension(W×H×L) | 11300×2350×2550mm |

| Machine net Weight | 4500kg |

| Repeat locating accuracy | ±0.02mm |

| Processing accuracy | ±0.1mm |

| Cutting surface roughness | Ra12.5 µm |

- High-speed electric motorized spindle imported from Italy;

- The tool magazine supply 12 cutter positions, the cutter can change quickly.

- Double-worktable once clamping can process two profiles at the same time.

- Overall steel welding machine, done by harsh aging treatment with high rigidity. The movement parts are all linear guide pair with high precision.

- SIEMENS Control System with High Quality and Reliable Stability