- Overview

- Product Description

- Primary Technical Data

- Technical Support

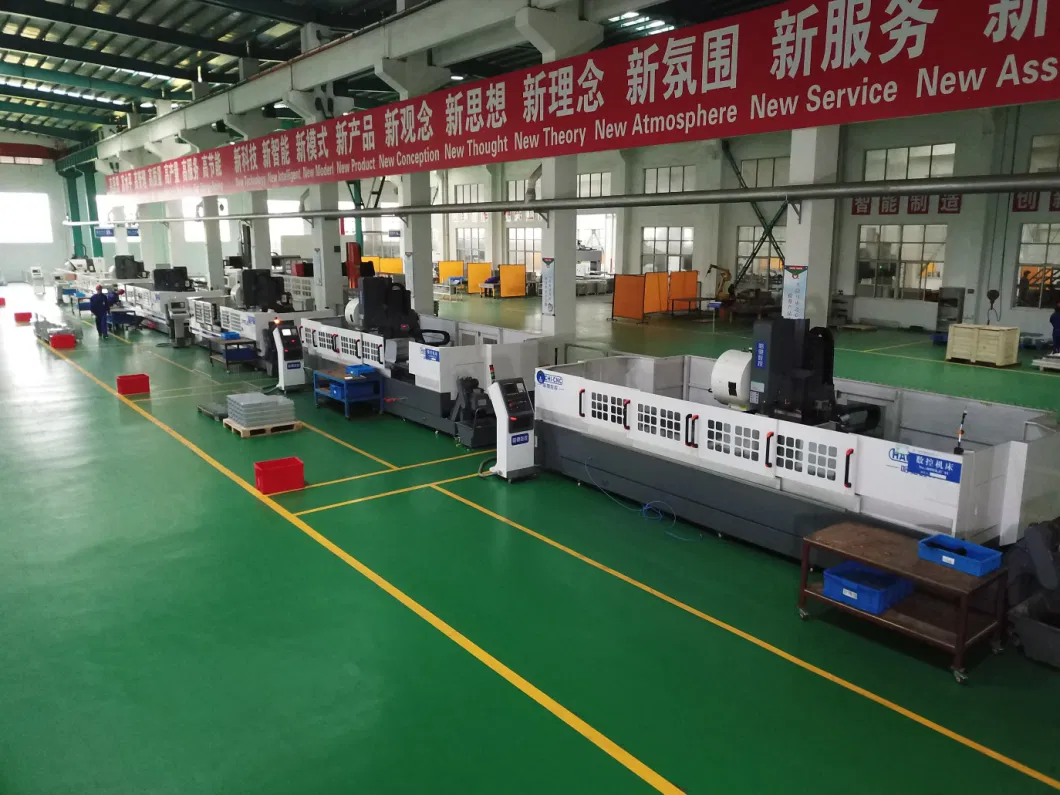

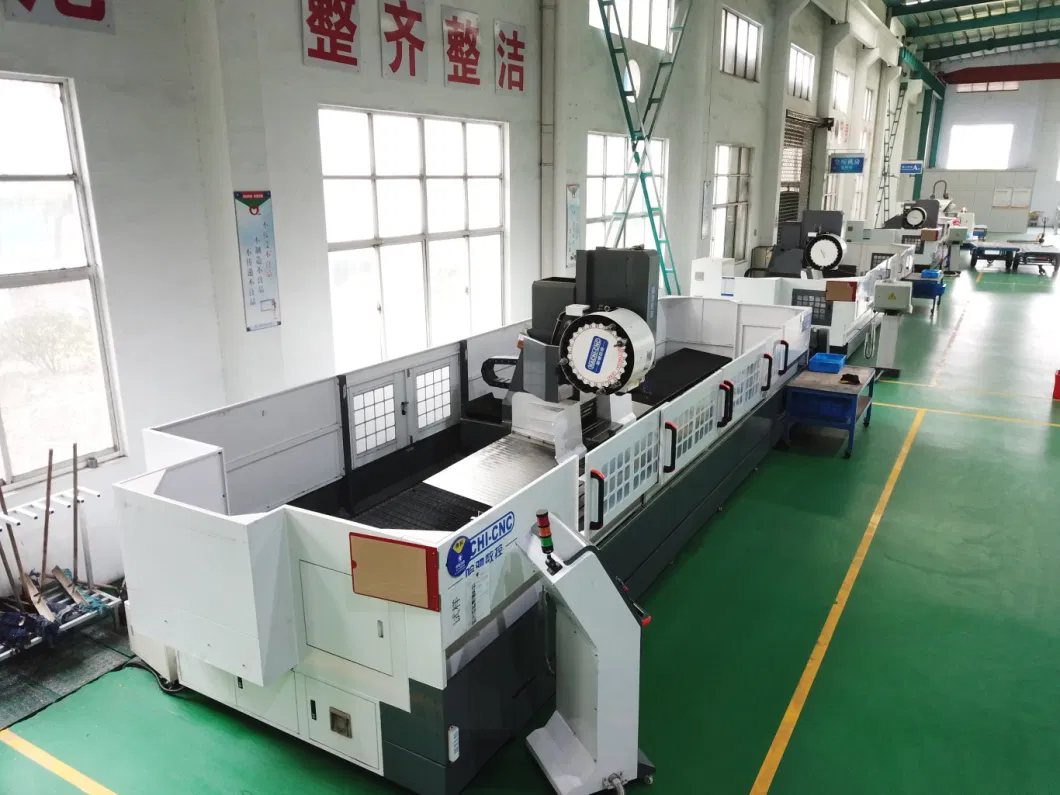

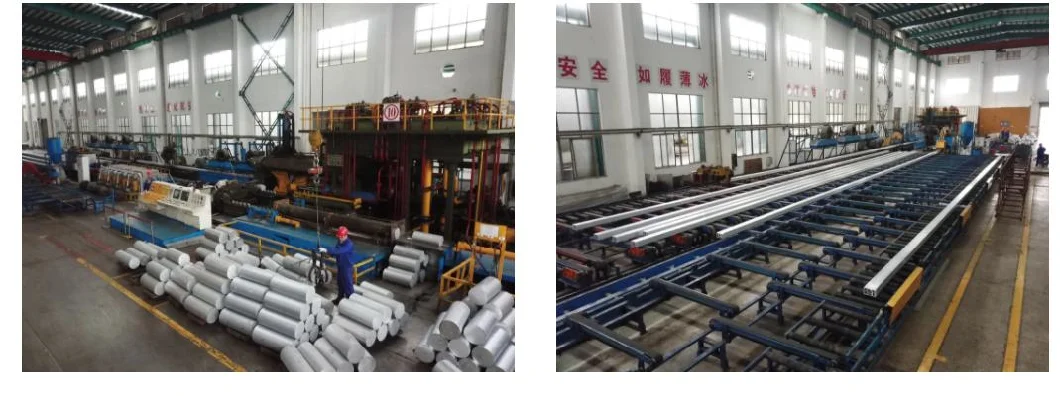

- Factory Equipment

- Certifications

- Company History

- Project

Basic Info.

Packaging & Delivery

Product Description

MetalPlus manufacture a wide range of high quality and customized standardized enclosures. We offer a variety of electronic industrial enclosures: aluminum profile housing, , die-cast aluminum box , standard aluminum chassis, rack mount housing, CNC precision machined parts, etc...

One of our special advantages is the custom aluminum profile housing. Use state-of-the-art CNC processing equipment to manufacture enclosures based on customer's exact specifications. We can deliver finished products on time and in a timely manner.

| Brand Name | MetalPlus |

| Material | 6063,6005,6061,6060 etc |

| Thickness | General profile thickness:0.8-5.0 mm; Anodized protection thickness:8-25 um; Powder coating color thickness 40-120 um. |

| Diameter | 50-800mm |

| Color | Silver, bronze, black,gold, blue, grey, champagne, bright, as your requests. |

| Templer | T4 T5 T6 T66 |

| Shape | square, flat, round, hollow, oval, triangle, U-profiles, L-profiles, T-profiles, H-profiles, customized available |

| Surface Treatment | Mill finish, anodic oxidation, powder coating, eletrophoresis, PVDF coating etc . |

| Products Classification | 1) General aluminum profiles: various shapes of pipes and tubes, angles, T or U shapes etc. |

| 2) Industrial aluminum profiles: Heat sink, enclosures of chargers closet frame, furniture frames, LED lighting, Guide Rail etc. | |

| 3) Construction aluminum profiles: Aluminum doors & windows, Sliding Windows, Roller shutter door, Curtain track | |

| 4) OEM & ODM: accept customers' own designs and drawings of aluminum products | |

| Deep processing: | Cutting, punching, drilling, tapping, milling, bending, welding etc. |

| Manufacture technological process | Aluminum ingot → Melting and casting → Extrusion → Surface Treatment → Acceptance test → Packing → Warehouse → Delivery |

| Certification | ISO 9000; ISO 9001; ISO 14000; CQC; RoHS |

| Markets we sold | Germany, North America, Africa, and European countries and area |

View more products you can click the following product keywords :

Surface Treatment

| Mill finish | Raw materials aluminum ingot purity 100% performance to adopt various processing secondly |

| Finish of aluminum itself with a natural anodic layer formed in the air , weak corrosion resistance | |

| Anodizing | Oxidation film thickness more than 10um , even color , without mechanical lines, corrosion-resistant , durable ,shinning and decorative. |

| Available in different colors like metal silver, champagne, dark bronze, black, and the same color with matt effect | |

| Electrophoresis | 20 years quality assurance, color elegantly and even color, surface without grain, glossy surface, corrosion-resistance, highly-wear resistance , high surface and brightness |

| Available in different colors like metal silver, champagne, black, and the same color with matt effect | |

| Powder coating | Film thickness more than 40 um , surface smoothly , colorful products with various mechanical performance to adopt all kinds of architechtural style |

| Silver, Bronze, champagne ,Matte,Natural for andodizing | |

| Wooden grain | New technology in finishing to form a texture look like real wood . 20 years quality assurance, corrosion-resistance, durable , shining and decorative. |

| Available in types of wood pattern. Hand touch or film transferring are both available. Customized accepted. | |

| Polishing | By buffing and chemical process to form mirror like finish, suitable for decorative application |

| Available in all kinds of color | |

| Brushed | By brushing and chemical process to form shining with line, suitable for decorative application |

| Available in all kinds of color |

Product components:

| PARTS | ||||

| S/N | PART NAME | QTY | MATERIAL | |

| 1 | Extrusion profile | 1 | AL6063 | |

| 2 | Front and rear panels | 2 | AL | |

| 3 | Screws | 4/8 | SS | |

Specifications :

1.Aluminum top+bottom plate with Aluminum case design.Suitable for rail transit, new energy,power equipment, meteo rological testing, marine monitoring and other application fields.

2.The extruded aluminium frame and diecast aluminium panels makes it extremely suitable to be used hostile environments where waterproofing and heat dissipation is essential.

3.PCB or chassis can be mounted by sliding it horizontally into inner-grooved body frame.

4.Suitable for measuring instruments, industrial control box, and industrial camera housing,wiFi outdoor access points. outdoor lot qatewavs.

Advantage of our enclosure :

Excellent material for smooth and subtle edges.

Elegant appearance.

Surface treatment: colorful anodized or electrostatic powder coated.

Suitable for constructions and other industrial purposes.

Customized surface finishes are welcome.

Advantage :

1. Over 17 years aluminum industrial experience and strong team;

2. Full inspection of products before shipment;

3. Complete production processing line, from melting, extrusion, powder coating, anodizing and wood grain, also with deep processing capacity.

4. ISO9001: 2008, ISO14001: 2004, ISO10012, AA grade standardize corporate;

5. Multi business scope, various types of products, ensures market shares.

6. OEM and ODM are available.

Application :

Inverter , Signal-Amplifier ,Video Pusher , Changer of Lithium-Ion Battery ,Mini Host

1) Chemical composition

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Impurity | Al |

| 6063 | 0.2-0.6 | 0.35 | 0.1 | 0.1 | 0.45-0.9 | 0.1 | 0.1 | 0.1 | 0.15 | Rest |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.15 | Rest |

| 6060 | 0.3-0.6 | 0.1-0.3 | 0.1 | 0.1 | 0.35-0.6 | - | 0.15 | 0.1 | 0.15 | Rest |

| 6005 | 0.6-0.9 | 0.35 | 0.1 | 0.1 | 0.40-0.6 | 0.1 | 0.1 | 0.1 | 0.15 | Rest |

2) Mechanical property

| Alloy | Temper | Tensile strength | Yield strength | Elongation |

| 6063 | T5 | ≥ 160Mpa | ≥ 110Mpa | ≥ 8% |

| T6 | ≥ 205Mpa | ≥ 180Mpa | ≥ 8% | |

| 6061 | T6 | ≥ 265Mpa | ≥ 245Mpa | ≥ 8% |

1. Based on the customer's requirements, we help design the appearance of the extruded profiles, provide CAD drawings and 3D models for customer confirmation, customize the molds, and extrude the aluminum profiles that meet the customer's requirements.

2. For customers with design capabilities, our professional R&D team will analyze and optimize the design based on the customer's drawings and our experience in extrusion processing, using the most reasonable design to reduce production costs and improve product performance.

3. Our company adopts a "one-stop" service and production model, including product design, customized molds, aluminum bar melting and casting, extrusion profiling, precision machining, and surface treatment. We can effectively control the alloy composition of raw materials and maintain product accuracy throughout the production process, providing you with high-quality products.

Extrusion

Equipped with 44 aluminum extrusion lines, MetalPlus is capable of producing various standards of commercial aluminum profiles and industrial aluminum profiles with maximum outer diameter of 350mm.

MetalPlus has 44 aluminum profile extrusion lines equipped with PLC control systems and precise molds. The largest extruder used in the MetalPlus factory is a 6800 ton unit. The machine is used for the production of industrial profiles in various shapes with a maximum diameter of 600mm. This allows us to satisfy the different requirements of our various customers. Some of the aluminum products produced by MetalPlus include radiators, industrial fan blades, motor enclosures, solar cell frames, doors, and windows.

MetalPlus can produce custom molds according to customer requirements. We have the abilities and experience to produce aluminum profiles with complex structures. We have our own R&D team so we can provide reasonable suggestions for our customers in order to create superior products at affordable prices.

Anodizing

Anodizing is a process in which a layer of aluminum oxide is formed on the surface of aluminum alloy products when they are placed in an electrolyte solution and then an electrical current is applied. Oxidized aluminum profiles feature improved corrosion resistance so that the surface can withstand various weather conditions. Meanwhile, the aluminum oxide also increases the product's hardness and wear resistance. MetalPlushas 6 anodizing production lines. The profiles processed in our anodizing lines feature uniform oxidation film thickness and color giving them a beautiful appearance. The oxidized profiles come in various color options including silver, black, gold, champagne, and imitation steel. Other colors can be customized upon request.

The anodized products will all be inspected by highly trained professional inspectors. Defective products which cannot be re-processed will be directly scrapped. Products with uneven color will be de-coated and re-anodized until they can meet the requirements. This ensures that there is no color difference among each batch of products.

Painting

Our factory is equipped with 4 powder spraying lines and all of them are using high-quality spray nozzles from Gema Switzerland. In the meantime, MetalPlus only uses safe and environmental friendly paint with strong adhesive force as well as durable color retention.

CNC Machining

MetalPlus is equipped with highly advanced machining equipment sets. All fine machining processes are accomplished by technicians with rich industry experience. Strict industrial standards are adopted during production to ensure fine machining precision and product quality.

1. MetalPlus has 12 PRATIC machining centers which can be used for the milling, drilling or tapping of profiles from different angles. They are especially suitable for the production of long profiles up to 6 meters. The equipment sets can realize machining of complex profiles with the simplest methods

2. MetalPlus has fully automatic cutting machines from Wegoma which can accomplish precise cutting with automatic and continuous material feeding, which means that the machines feature low labor cost and high production efficiency. Therefore, the cutting price of MetalPlus is significantlylower than that of the other enterprises in the industry.

3. We have 30 punching machines of which the punching pressure ranges from 50 to 100 tons. They can be used for the punching of relatively thick profiles of which the thickness can be over 5MM. There are also 10 stretch bending machines/bending machines which can realize bending of profiles to arc or different angles. The machining angle is highly precise. The factory is also equipped with 10 milling machines, realizing machining of different planes, bevels or grooves so that we can satisfy different machining requirements of our customers.

Packing and Shipping

In 2004 "THE RECOGNIZED BRAND OF THE BUILDING INDUSTRY MATERIAL MARKET"

In 2006 "CERTIFICATE FOR PRODUCT EXEMPTION FROM QUALITY SURVEILIANCE INSPECTION " and "ISO9001"

In 2009 "ADVANCED COMPANY "

In 2009 "JIANGSU FAMOUS BRAND CERTIFICAT "

In 2009 "CERTIFICATE FOR CREDIBLE PRODUCT OF QUALITY IN JIANGSU PROVINCE"

In 2012, Established the business relation ship with Panasonic , LG .

In 2015, be and inovative producer an supplying partner for Germany Client .

In 2017, Developed the new products of baseboard heaters .

In 2019, Cooperate with the world's largest Heater Manufacturers , and supply the Aluminum Shells for them .Won a good reputation !

In 2023, We will confidence to develop oversea distributor , to expand market for win-win benefits .

We are very honored to participate in the construction of the project as the main supplier of aluminum!

The Soccer City Stadium won unanimous praise after it was built!

Our professional R&D team analyze and improve upon Lobster's designs and then process them with our excellent processing equipment , exquisite technology . We minimize production costs and improve product performance thanks our optimization proficiencies.