Basic Info.

Model NO.

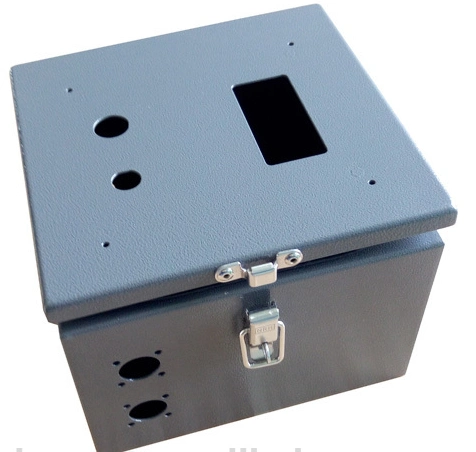

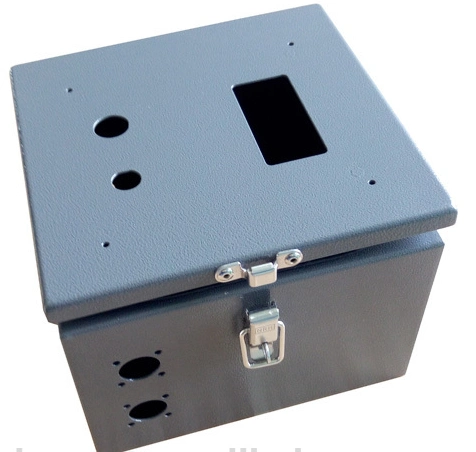

cabinet-32

Application Range

High-rise Buildings

Shell Material

Stainless Steel

Shell Protection Grade

IP56

Brand

Customized

Sample Lead Time

15-25 Working Days

Service

Quick Response and Immediate Action

Industry Standard

ISO-9001-2015 International Organization for Stan

Inspection

IQC, Ipqc, Fqc, QA

Sample

Available

Intended Application

Batteries, Connectors, Lighting Fixture etc.

Name

Electrical Box Cabinet

Transport Package

Inner-Plastic Bag; Outer -Standard Carton Box

Specification

Customized

Trademark

as Request

Origin

China

HS Code

7326901900

Production Capacity

2000000PCS/Year

Product Description

Customized LED Display Screen Electrical Power Distribution Cabinet

Workshop

Main products

Order Process

- Professional custom made electric box. More than 10 years experience.

- Custom made according to the drawings provide by customers. We can also provide the design service.

- All kinds of production machinery: laser cutting, CNC punching, bending, welding.

- There is Powder coating workshop specially for cabinets.

- OEM ODM is available.

| A | Material | Stainless steel, iron ( SPCC, SECC, SPTE, tinplate), aluminum alloy, red copper, brass, bronze alloy are available. |

| B | Workmanship for manufacturing | CNC Laser Cutting ,Stamping, Punching , Bending, turning ,Welding, roll-in, surface treatment, and other General Fabrication Service |

| C | Surface Treatment | Powder coating, Zinc plating, hot-dip, Silkscreen, polishing and so on. |

| D | Equipment | We own more than 300 sets CNC machines Laser cutting machine; CNC shearing machine; CNC Puching machine; CNC bending machine; Laser welding machine; Tig welding machine; Mig welding machine; Spot welding machine; Stamping machine; Rolling machine; Turning machine; Milling machine; Grinding machine; |

| E | Quality control | ISO90001:2008 and ERP management systems are strictly carried out.Stable quality and on-time delivery have won trusts and supports from our customers home and overseas. |

| F | OEM experienced | OEM Service based on drawings or samples from customers. |

Workshop

Main products

Order Process

| 1.Sample/Drawing | We need your detail require clearly. |

| ↓ | |

| 2.Negotiation | Material, cavity, price, delivery time, payment term, etc. |

| ↓ | |

| 3.Place order | According your own design or choice our design. |

| ↓ | |

| 4.Mould design | We will communicate&exchange the opinion with you during making drawing |

| ↓ | |

| 5.Tooling mould | After custome approve the mould design will start making mould. |

| ↓ | |

| 6.Product processing | Provide photos for customer show them tooling process |

| ↓ | |

| 7.Sample confirm | Send you sample for confirmation, if it is not satisfied by customer. We modify mould. |

| ↓ | |

| 8.Delivery product | Delivery product after customer approve sample and arrange shipment. |