Basic Info.

Model NO.

ZTXF-200

Application

Office Buildings, Hospital, Hotel, Workshop, Const

Frame Structure

Galvanized Steel Frame

Window

Steel Security Door

Door

PVC Sliding Window

Roof

Sandwich Panel+ Decoration Ceiling

Wall Panel

50mm/75mm/100mm/150mm Sandwich Panel

Floor

PVC Leather, Cement Particle Board

Color

White,Blue,Green,Red,Yellow or Customerized

Dimension

6000X2440X2920mm or Customerized

Shipping

6units/40hq

Certificate

Ce ISO

Warranty

Two Years

Key Words

Prefab Container House

Transport Package

40hq Container

Specification

6000*2440*2920mm

Trademark

ZONTOP

Origin

Shandong, China

Production Capacity

5000

Product Description

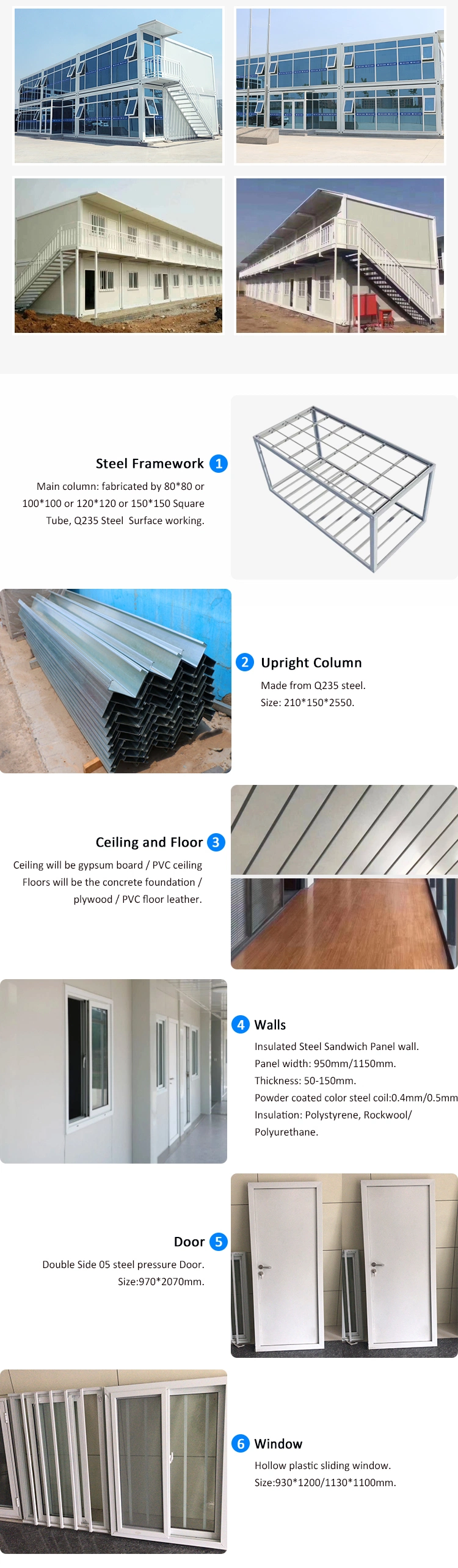

CE ISO Engineering projects two storey luxury 20ft container house for office

Product Introduction

1. The container house is made by steel frame structure, which adopts Hot-form galvanized steel.

2. Structure is consists of three modular parts: roofing frame, corner column and floor frame.

3. Each modular is manufactured at the factory and assembled on construction site.

4. With one single container house as basic unit, it can be combined horizontally or vertically in different form like building blocks.

5. Flat pack container house can be stacked in three storeys with flexible in space layout and multiple function, and can be used in different application fields.

Product Advantages :

1.Flexible combination,modular house can be easily combined, time and labor saving.

2.Easy assembly. We provide install drawings and video.

3.Good insulation. It can suffer extreme climate.

4.Good looking and neat inside.

5.Good resistance for water,wind and earthquake.

6.long lifespan 15-20 years

7.Comfortable for living and working.

The main features for container house:

1) It could be widely used as house, office,meeting room,dormitory, storage, shower rooms,guard, toilet,hotel, shop, restaurant, booth, kiosk etc.

2) Several units could be combined and stacked to be a big beautiful building based on customized designs, with inside,outside, stairs, aisles and porch container house.

3)It could be assembled and disassembled by hands, 100% nut-bolt connection, two men could install one set in 2hours.

4)The top and bottom main steel frames were welded separately, upgrade and strengthened panels, door, window, it is of high firmness and excellent performance of waterproof, thermal and sound insulation with long service.

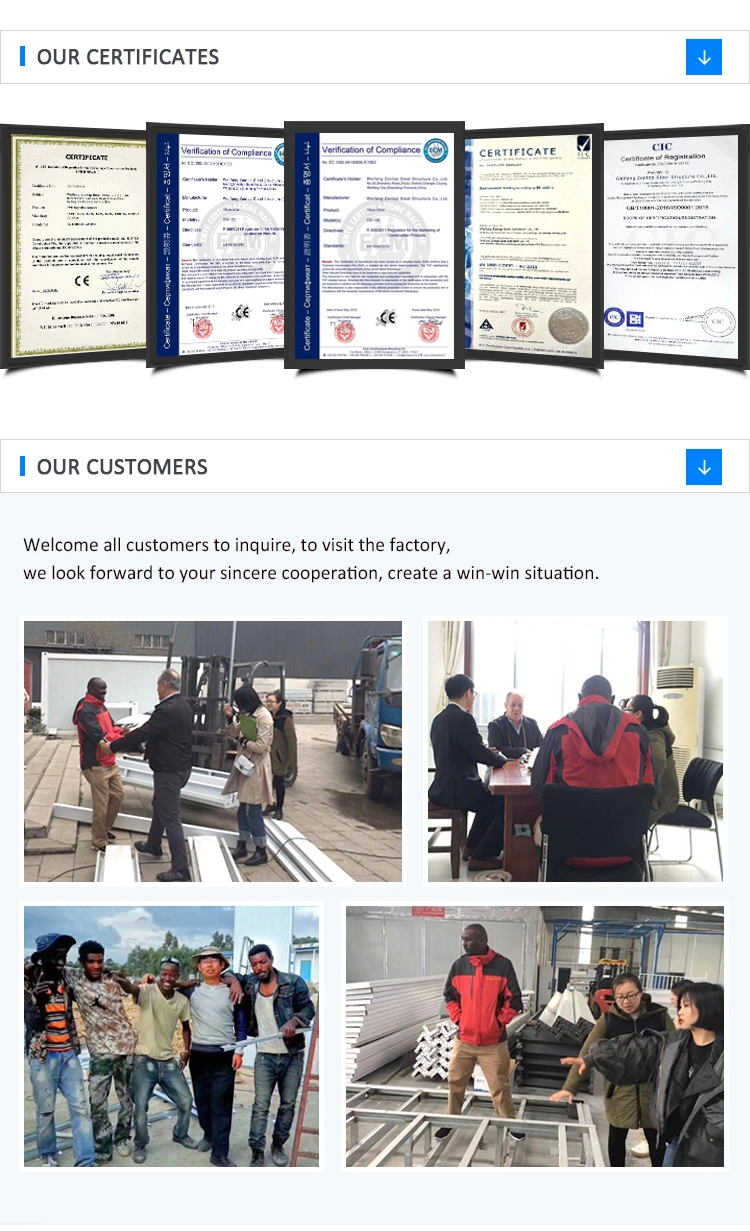

The features of sandwich and frame

1) Light weight.

2 )Strong fire and corrosion resistance.

3) Heat absorption and sound insulation.

Frame: Q235 Strip Steel

Hot rolled galvanized, anti-corrosive coating,

Thickness: 2.5/2.7/3.0 mm

Corner post: Galvanized, anti-corrosive2.5/ 3.0mm

Connection: high-strength bolt M12*40

Detailed Dates for Specifications (Standard container house)

Product Introduction

1. The container house is made by steel frame structure, which adopts Hot-form galvanized steel.

2. Structure is consists of three modular parts: roofing frame, corner column and floor frame.

3. Each modular is manufactured at the factory and assembled on construction site.

4. With one single container house as basic unit, it can be combined horizontally or vertically in different form like building blocks.

5. Flat pack container house can be stacked in three storeys with flexible in space layout and multiple function, and can be used in different application fields.

Product Advantages :

1.Flexible combination,modular house can be easily combined, time and labor saving.

2.Easy assembly. We provide install drawings and video.

3.Good insulation. It can suffer extreme climate.

4.Good looking and neat inside.

5.Good resistance for water,wind and earthquake.

6.long lifespan 15-20 years

7.Comfortable for living and working.

| Item | Materials |

| Dimension | Length: 6055mm |

| Width: 2438mm (Can up to 3000mm) | |

| External Height: 2920mm | |

| Internal Height: 2520mm | |

| Weight | 18000 |

| STEEL FRAME | 1.Material: Q235 galvanized steel; thickness, 2.5~4.0mm 2.Support:C100x40x2.0 or C80x40x1.2 purlin 3.Connection: high strength bolt M12*40 4.Surface working: sand blasting, epoxy basic painting 55μm, final vinyl acrylic painting 55μm thick Top and bottom gray (rust-proof primer, gray finish) Column: 210x150x2550mm 2.5mm--4pcs |

| Wall | Wall Panel: 75mm thickness glass fiber sandwich panel 0.5mm colored steel |

| ROOF | Outside Steel: 0.5mm steel sheet Keel: C80x40x20x2.0 or C80x40x1.2 steel purline Insulation Layer: 100mm thickness fiber glass(16kg/m3), Fire-proof level: A Ceiling: 0.5mm colored-steel +Ceiling aluminum edge Rainspout:Water flow to the four corner |

| FLOOR | Material: Q235 galvanized steel; thickness, 2.5~4.0mm Keel: C100x50x2.0 or C100x50x1.5 square tube,galvanized steel Insulation Layer: 100mm thickness fiber glass Cement floor: 18mm thickness cement particle board Surface: PVC Floor leather (thickness 2.0mm) |

| Doors | 0.5mm double-sided steel security door Size: 970x2070mm 840x2070mm Lock: high quality press lock |

| Windows | Windows : Plastic steel hollow glass sliding window (usually 2pcs) with screen window and security net Size: 930x1200mm |

| Electricity System | Double tube fluorescent light (usually 2 pcs) Distribution board: CE approval (1 pcs) The lines inside the wall panels Electrical wire, 2.5mm2 for lighting system, 4mm2 for AC units. copper core 3 sets of 16A five holes universal socket and 1 air conditioning socket Electrical distribution box + breakers + earth leakage protective device Voltage: 110~220V, 50~60Hz |

| Others | Lift corner piece Rainspout: Φ50PVC pipe and others |

| Optional | 1.Exhaust fan 2. Floor heating: 100mm thickness fiber glass(16kg/m3), Fire-proof level: A 3. Sanitary ware: Western Close tool: ceramic, with pipes and installation fittings Urinal: ceramic, with pipes and installation fittings Wash basin: ceramic, with post, faucet, pipes and installation fittings Shower head, Shower base, Water mixture 4. Air condition 5. Office furniture |

| Packing | 6sets in a 40GP/40HQ container |

The main features for container house:

1) It could be widely used as house, office,meeting room,dormitory, storage, shower rooms,guard, toilet,hotel, shop, restaurant, booth, kiosk etc.

2) Several units could be combined and stacked to be a big beautiful building based on customized designs, with inside,outside, stairs, aisles and porch container house.

3)It could be assembled and disassembled by hands, 100% nut-bolt connection, two men could install one set in 2hours.

4)The top and bottom main steel frames were welded separately, upgrade and strengthened panels, door, window, it is of high firmness and excellent performance of waterproof, thermal and sound insulation with long service.

The features of sandwich and frame

1) Light weight.

2 )Strong fire and corrosion resistance.

3) Heat absorption and sound insulation.

Frame: Q235 Strip Steel

Hot rolled galvanized, anti-corrosive coating,

Thickness: 2.5/2.7/3.0 mm

Corner post: Galvanized, anti-corrosive2.5/ 3.0mm

Connection: high-strength bolt M12*40

Detailed Dates for Specifications (Standard container house)

| 1 | Live load capacity of roofing | 0.6kn/m2 |

| 2 | Second Floor Load Capacity | 150 kg/m2 |

| 3 | Live load of corridor | 2.0kn/ m2 |

| 4 | Wall permitted loading | 0.6KN/ m2 |

| 5 | Ceiling Permitted live loading | 0.5 KN/m2 |

| 6 | Wall Coefficient of thermal conductivity | K=0.442W/m2k |

| 7 | Ceiling Coefficient of thermal conductivity | K=0.55W/ m2K |

| 8 | External and internal wall heat transmission coefficient | 0.35Kcal/m2hc |

| 9 | Wind resistance | Grade 11 (wind speed≤ 120km/h) |

| 10 | Earthquake resistance | Grade 10 |